The Ultima Range The Ultima compressor belongs to the innovative range of compressors from CompAir and it's 100% oil and silicone free.

The unique design utilises a low pressure and high dry screw airend – each airend is individually driven by a variable speed, permanent magnet electric motor , offering exceptional levels of efficiency versus traditional oil-free technology. The design of Ultima combines the ultimate performance with the ultimate efficiency, and still delivers a footprint 37% smaller than a conventional two-stage oil-free compressor. CompAir‘s Ultima compressor is extremely quiet with a noise level of only 66dB(A). This is an excellent benefit for patrons who want to use compressors at point of use, eliminating the necessity for sophisticated and expensive pipework and even further maximising efficiency. Ultima is that the first air-cooled, oil-free compressor on the market, capable of utilising heat recovery for process water heating. The Ultima technology can operate in either air-cooled or water-cooled mode or a mixture of both concurrently. By utilising the superior design of the closed-loop system water system, Ultima requires no air for internal cooling. Ultima processes cooling air within the compressor and utilising a device , cools the interior air, then recirculates it via the bottom frame round the compressor. This also ensures that no dust or particulate can enter the inside of the compressor. As a result, installation is formed easy with no requirement for ducting, compressor rooms are often kept to the minimum size, noise levels are greatly reduced and machines can be easily installed at point of use. The Delcos XXL system ensures reliable operation and protects your investment by continuously monitoring the operational parameters, essential for reducing your running costs. PureCARE is a specially designed service plan for the CompAir oil-free product range to make sure uninterrupted and uncontaminated compressed gas . Each PureCARE service plan is ready-made to your specific application and includes CompAir genuine spare parts.

0 Comments

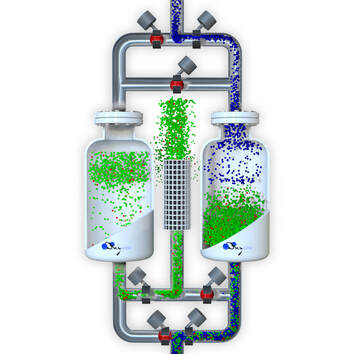

Do you purchase nitrogen gas through bulk delivery or as liquid nitrogen? There could be an alternative option for you! Here are the key benefits of on-site generation: Guaranteed supply Imagine no longer having to wait for a liquid nitrogen delivery? Relying on purchasing nitrogen means you can fall victim to unpredictable supply timescales, which could cause unplanned downtime. This problem is intensified if your business operates in a remote are or outside of the gas supplier’s main route! But have no fear, onsite generation increases efficiency as it allows you to work at maximum productivity and minimises downtime with an on-demand supply of nitrogen. Increased safety High pressure cylinders require heavy manual handling to move to or from storage, but are very dangerous if they are knocked over or mishandled, and must always be supervised. The storage of cylinders poses risk of explosive decompression or leaks. Even when they’re empty, these issues still pose a problem as the cylinders are very heavy! Nitrogen gas is produced at low pressure which eliminates the above safety hazards associated with bulk delivery options. Reduce wastage It is physically impossible to get every cubic foot of gas out of a cylinder due to progressively falling pressures and the accumulation of impurities. Each time a business returns “empty” cylinders to a gas company, they are effectively giving around 10% of the gas back. Nitrogen generators can be configured to meet your specific requirements. Equally it is easy to future proof in the event of demand increase as it scalable to meet future needs. Stop ongoing costs Investing in a nitrogen generator may seem like an expensive upfront cost. However, this purchase removes the need for ongoing costs such as equipment rental, re-supply ordering, delivery charges, contract commitments and many more. On-site nitrogen generation gives you more control over your production processes and you’ll no longer be thinking ahead to the next delivery. |

About usMulti-Pneumatics Ltd. was founded in 1985. Over the past three and a half decades, we have solidified our position as a leading supplier and service provider for compressed air and nitrogen equipment in Ireland.

|

Telephone(01) 460 2447

|

|

RSS Feed

RSS Feed